Armour Grey®

Armour Grey®

Armour Grey®

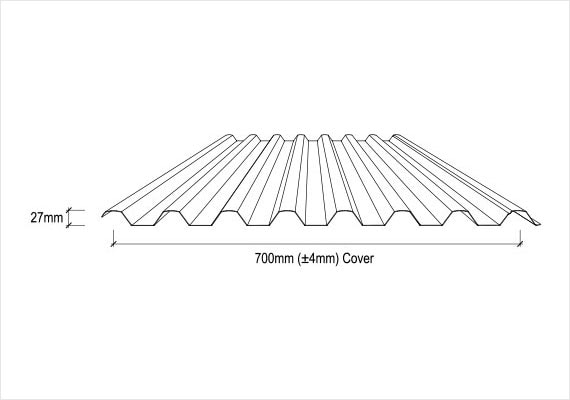

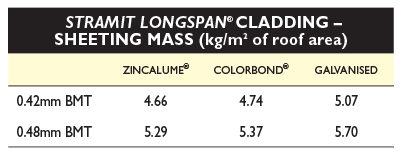

The roofing/walling shall be 0.42 (or 0.48) mm BMT Stramit Longspan® Roof and Wall Cladding in continuous lengths with trapezoidal ribs 27mm high, spaced at 100mm centres. Sheeting material shall be protected steel sheet to Australian Standard AS1397, with a minimum yield stress of 550MPa (Grade G550) and an AM100/AZ150 coating with an oven-baked paint film of selected colour, or a plain AM125/AZ150 coating.

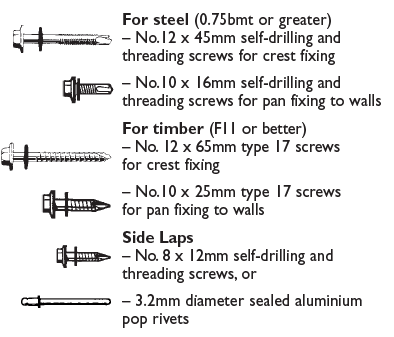

The sheeting shall be fixed to the purlins/girts in accordance with the manufacturer’s recommendations. Suitable fixing screws in accordance with Australian Standard AS3566, Class 3, shall be used at every support with side lap fasteners installed at mid span if required. Sheets shall be laid in such a manner that the approved side lap faces away from the prevailing weather.

A minimum of 50mm shall be provided for projection into gutters. Flashings shall be supplied in compatible materials as specified; minimum cover of flashing shall be 150mm. All sheeting shall be fixed in a workman-like manner, leaving the job clean and weathertight. Repair minor blemishes with touch-up paint supplied by the sheeting manufacturer. All debris (nuts, screws, cuttings, filings etc.) shall be cleaned off daily.

Class 4 fasteners should be used <1km from the coast.

Cyclonic data for Stramit Longspan® Roof and Wall Cladding can be found in the Stramit Cyclonic Areas Guide. Information on the use of Stramit Longspan® Roof and Wall Cladding in the Darwin area can also be found in deemed-to-comply sheets No M/147/01. This is available from Stramit or on the NT BAC website.

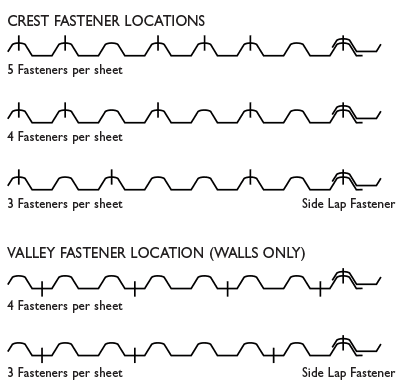

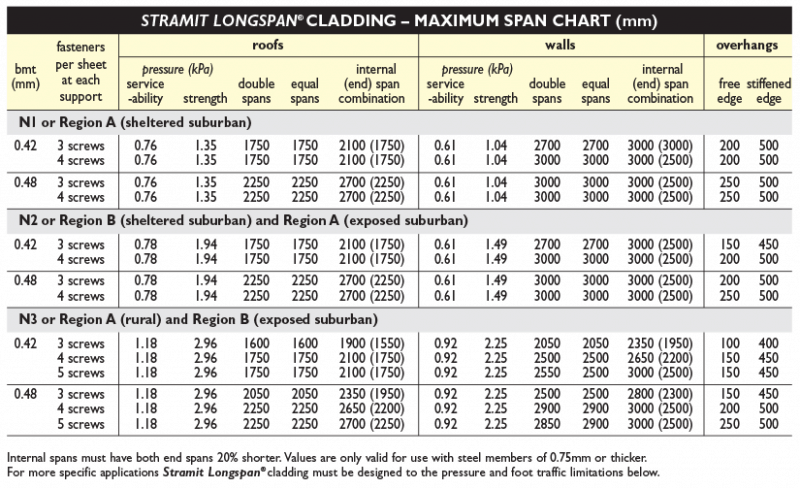

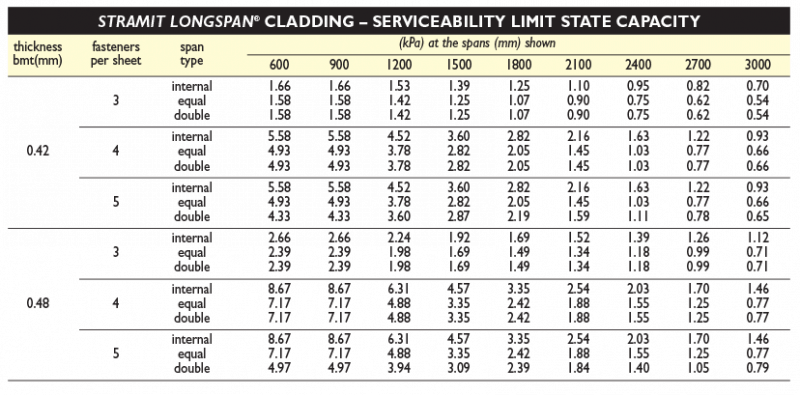

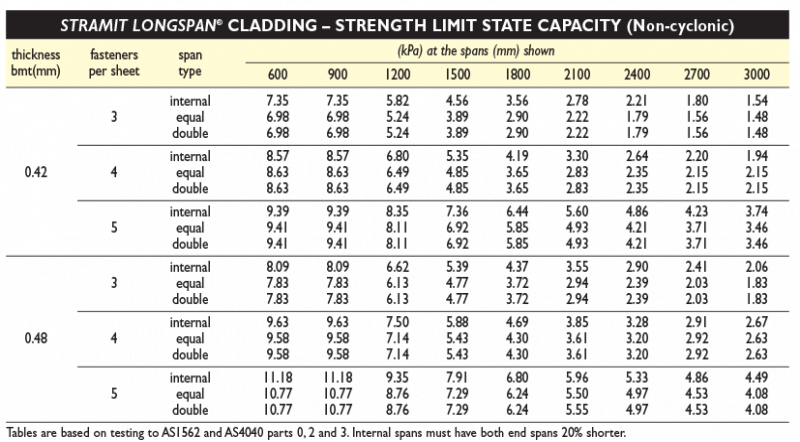

Stramit Longspan® Roof and Wall Cladding can be fixed with either 3, 4 or 5 fasteners per sheet at each batten/purlin to meet the required performance values.

All external fastening screws must conform to AS3566 – Class 3. They are to be hexagon headed and must be used with sealing washers for both roofing and walling.

For connecting to purlins or top hats use:

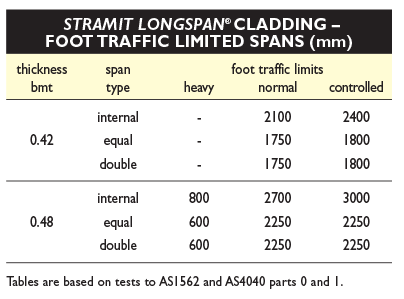

Foot traffic limits for Stramit Longspan® Roof and Wall Cladding are shown for 3 alternative foot traffic categories:

High Maintenance - for applications with repeated maintenance, particularly where personnel may be unfamiliar with correct procedures for walking on metal roofs.

Normal - based on traditional expectations, with moderate maintenance foot traffic using designated footpaths

Controlled - spans that confirm to AS1562 but require minimal careful foot traffic only on the designated footpath.

Suggested for use only where occasional aesthetic imperfections from foot traffic are acceptable.

For more information on foot traffic performance of Stramit's roofing profiles refer to Stramit's Foot Traffic Guide where tables are based on tests to AS1562 and AS4040 parts 0 and 1.

Stramit Longspan® Roof and Wall Cladding is manufactured from G550 colour coated steel or zinc-aluminium alloy coated steel. In some locations galvanised and severe environment colour coated steel may be available by arrangement.

Colour coated steels are in accordance with AS2728 – Category 3 and, for the substrate, with AS1397. Zinc-aluminium alloy coated AZ150, aluminium-zinc-magnesium alloy coated AM100/AM125 and galvanised Z450 conform to AS1397.

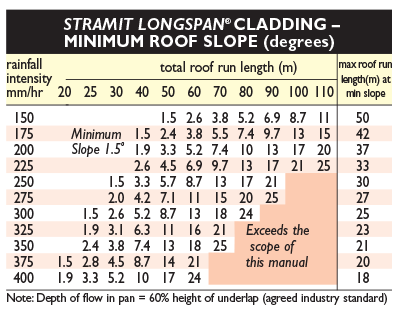

The minimum roof slope for Stramit® Longspan Roof and Wall Cladding is 3 degrees (1 in 20).

The spans shown below take account of normal foot traffic and wind resistance including local pressure zone effects. Pressures are based on AS4055 or AS1170.2.

Where the two standards differ, the worst case has been taken for each classification. Data should only be used for buildings 7m or less in height, 1000m2 or less in area and unaffected by land topography.

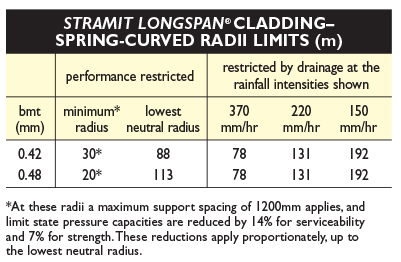

Stramit Longspan® Roof and Wall Cladding can be spring-curved, concave and convex, including curved ridges, provided it is sealed at the apex, and within the recommended limits.

The Stramit Spring Curving Guide has more detailed information.

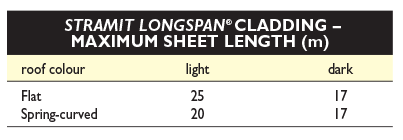

All metal roof sheeting is subject to thermal expansion and this needs to be accommodated where there is a temperature difference between the sheeting and the structure.

The colour of the sheeting will affect the amount of thermal expansion, and whether the sheet is flat or cured will affect its ability to resist without problems. Sheet lengths should be limited as follows.

Stramit Longspan® Roof and Wall Cladding has a superior water-carrying capacity, to most close pitched trapezoidal profiles. This and the decking stiffness enable roof slopes to be as low as 3.0° for many applications.

Roof run lengths are the combined lengths of all roof elements contributing to a single pan drainage path. This can include the roof length upstream of a roof penetration that concentrates flow into other pans.

The table below gives slopes for 100 year return period rainfall intensity.

Derived from testing, the following tables give the wind load resistance for both serviceability and strength limit states.

Stramit's cladding can be easily cut, where required, using a power saw with a cold cut saw blade or a power nibbler and, for localised cutting, tin snips. Avoid the use of abrasive discs as these can cause burred edges and coating damage. Please dispose of any off-cuts carefully and thoughtfully.

Stramit Longspan® cladding is readily installed with or without fibreglass insulation blanket. If practical lay sheets in the opposite direction to prevailing weather.

Installation of Stramit Longspan® cladding is a straightforward procedure using the following fixing sequence.

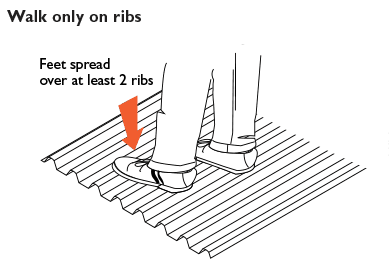

As with all roofing products, we recommend extra caution be taken when walking on the roof. When walking on Stramit Longspan® Roof and Wall Cladding, always wear flat rubber soled shoes and place feet only on the ribs, taking care to avoid the last rib or two near edges of the metal roof area.

At HMR Supplies, we provide you with corrugated metal roofing for a durable and aesthetically pleasing roof that will last for years after installation. If you're looking for an affordable way to protect your property from the elements, then corrugated metal roofing with corrugated metal roof flashing is just what you need. We offer a wide range of corrugated roofing and flashing products at HMR Supplies. Contact us today to learn more about how we can help you choose the right type of roofing material for your home or business.

02 9771 3777

02 9771 3777

02 9771 3777

02 9771 3777